Please fill aboving table and submit, you will see how many acetate temples could be produced by below table.

This calculator is used for eyewear designer to check the overall quantity of temples could be produced by particular size of acetate sheet. Please kindy note the result for reference only, and the caculator does not cover all the occasions involved in eyewear frame manufacturing.

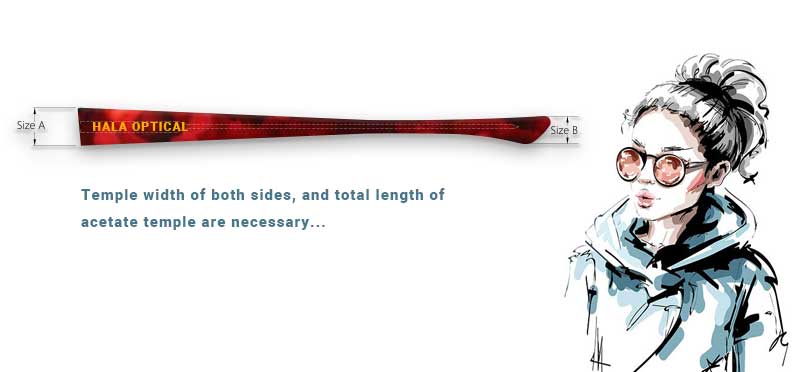

| Temple Width A | Temple Width B | Temple Length | Acetate Sheet | Temple Quantity (pairs) |

|---|

The calculator in this page is an attempt from Hala Optical to offer advanced service to our valued partners.

Calculating the quantity of eyeglass frame temples before cutting acetate sheets is an essential step in the manufacturing process to ensure efficient use of materials and minimize wastage.

There are several factors should be considered before cutting acetate sheet, such as eyeglass temple length, temple width, spacing and so on.

- Temple Length: Determine the desired length of the eyeglass frame temples based on the design specifications and standard temple lengths. Temple lengths can vary depending on factors such as frame style, fit, and wearer preferences.

- Acetate Sheet Size: Measure the dimensions of the acetate sheet available for cutting. Acetate sheets typically come in standard sizes, and the dimensions will influence how many temple pieces can be cut from each sheet.

- Temple Width and Thickness: Consider the width and thickness of the temples required for the eyeglass frames. These dimensions will affect how many temple pieces can be obtained from a single acetate sheet, as well as the overall strength and durability of the temples.

- Spacing Between Temple Pieces: Determine the spacing needed between individual temple pieces to accommodate cutting tools and minimize material waste. This spacing will depend on the cutting method used and the precision required for the manufacturing process.

- Optimization: Use software or manual calculations to optimize the layout of temple pieces on the acetate sheet, ensuring maximum utilization of space and minimizing material wastage. Consider factors such as orientation, nesting, and arrangement to achieve the most efficient cutting layout.

- Patterned of Acetate: If working with patterned acetate sheets, take into account the alignment and orientation of the patterns when laying out temple pieces to ensure a consistent and aesthetically pleasing finish in the final eyeglass frames.

By accurately calculating the quantity of eyeglass frame temples before cutting acetate sheets, eyeglass manufacturers can streamline the production process, reduce material waste, and optimize resource utilization, ultimately contributing to cost-effectiveness and sustainability in eyewear manufacturing.